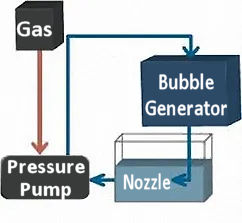

GBB (Green Blue Bubble) System

GBB (Green Blue Bubble) System

Fine bubble x Energy saving, Water saving,

Reduction environmental impact ===> SOLUTION

GBB (Green Blue Bubble) system is used in a variety of industries.

It is also characterized by its ability to scale up from small to large.

With its options, we provide extensive follow-up services from process control, monitoring, etc. to periodic maintenance.

|

Textile and animal hair cleaning FJP-150 150m3/Hour Air fine bubbles are generated in the plant’s storage tank (20 m3) and provided to the plant’s cleaning water to improve cleaning efficiency. Effect: 180 m3/day animal hair manufacturing plant Water savings: approx. 6,500 m3/year Heavy oil A: approx. 18 kL/year CO2 reduction approx. 52 t/year |

Fine bubbles of Oxygen are provided to the nutrient solution tanks of hydroponic cultivation to increase the weight of lettuce. Effect: 2,000 bags/day lettuce production plant Monthly shipments: Raised 10-15% or more Improved individual rubberization and reduced number of discards

|

Tanning wastewater treatment plant FJP-6 100L/min Because of the high concentration of hydrogen sulfide in the incoming wastewater, the concentration of hydrogen sulfide is rapidly reduced by aeration with oxygen fine bubbles. Effect: Hydrogen sulfide concentration 50ppm → 5ppm or less Improvement of bad odor

|

Wastewater treatment facility FJP-300 300m3/Hour Provides highly concentrated oxygen fine bubbles to further activate microorganisms. Ability of purification is increased, energy is saved, and sludge volume is reduced. Effect: Wastewater treatment facility with 200 m3/day Reduction of BOD/COD by about 15-20 Sludge (industrial waste volume): 20-30% reduction |

Metal manufacturing plant FHP-100 100L/min Highly concentrated fine bubble water is used to improve the finish (degreasing) of metal processing plants. We provide fine bubble water by using a pressurized pump in a conventional system. Effect: Use of 80 m3/Day of water Water savings approx. 2,000 t/year Heavy oil A approx. 8 kL/year CO2 reduction approx. 20t/year |

Control system

Controls fine bubble system. The system performs time control, concentration control, Web monitoring, and remote monitoring. The system performs detailed control, from stopping and responding in case of abnormality, to providing information for Web display and issuing e-mail alerts.

|

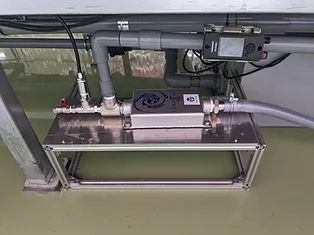

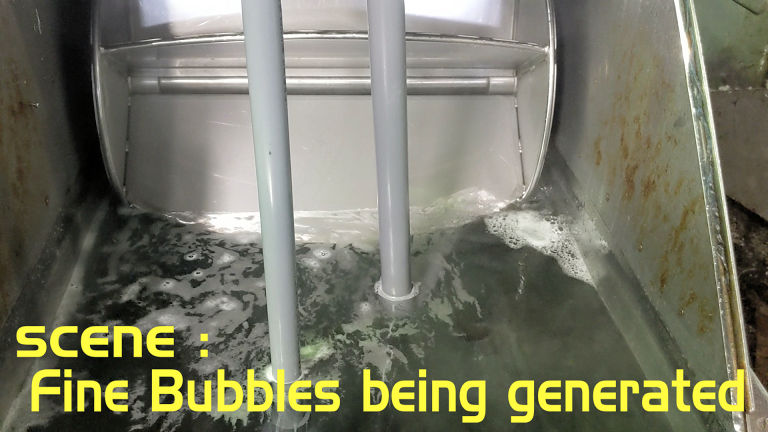

Video of Fine Bubbles being generated

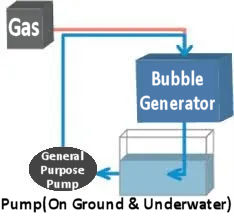

Design Philosophy – Green Blue Bubble’s “One-Stop Solution”

Bubble Generator Lineup

| Model type |

FJP-6 | FJP-12 | FJP-24 | FJP-40 |

|---|---|---|---|---|

| Processing volume |

6 m3/Hour |

12 m3/Hour |

24 m3/Hour |

40 m3/Hour |

| Gas supply |

3 L/min |

6 L/min |

10 L/min |

20 L/min |

| Inlet pipe size |

1 inch |

1 1/4 inch |

1 1/2 inch |

2 1/2 inch |

| Outlet pipe size |

1 1/4 inch |

1 1/2 inch |

2 inch |

4 inch |

| Pump Output |

0.4 kW |

1.2 kW |

2.2 kW |

3.7 kW |

| Size LxWxH (mm) |

137 × 180 × 670 |

160 × 220 × 758 |

510 x 635 x 1530 |

455 x 790 x 1765 |

| Weight | 3.5kg | 6kg | 60kg | 120kg |

■FoamJet / Large volume type (number density N x 10 million pieces)-2

| Model type |

FJP-60 | FJP-100 | FJP-150 | FJP-300 |

|---|---|---|---|---|

| Processing volume |

60 m3/Hour |

100 m3/Hour |

150 m3/Hour |

300 m3/Hour |

| Gas supply |

30 L/min |

40 L/min |

60 L/min |

100 L/min |

| Inlet pipe size |

4 inch |

4 inch |

6 inch |

8 inch |

| Outlet pipe size |

4 inch |

6 inch |

6 inch |

10 inch |

| Pump Output |

5.5 kW |

7.5 kW |

15 kW |

22 kW |

| Size LxWxH (mm) |

490 x 865 x 2070 |

1140 x 970 x 2400 |

1230 x 1130 x 2705 |

1410 x 1380 x 3540 |

| Weight | 270kg | 380kg | 470kg | 670kg |

*The size and weight of the generator itself are indicated for FJP-6 – FJP12.

*The total size and weight of the pump and plinth are indicated for FJP-24 and larger generators.

*Gas supply volume and pump output are for reference only.

Each system will be designed according to the conditions of the site.

FJP-12 FJP-150

■Fabby High concentration type (Number density N x 100 million pieces)

| Model type |

FJN-15I-N04Z | FJN-25I-N15Z | FJN-50I-U37Z-A | FJN-50I-S150Z-A |

|---|---|---|---|---|

| Processing volume |

10 L/min |

50 L/min |

100 L/min |

340 L/min |

| Gas supply volume |

0.5 L/min |

2.5 L/min |

5 L/min |

17 L/min |

| Inlet pipe size |

1/2 inch |

1 inch |

2 inch |

2 inch |

| Outlet pipe size |

1/2 inch |

3/4 inch |

1 1/4 inch |

2 inch |

| Power consumption | 0.6 kW |

2 kW |

3.7 kW |

17 kW |

| Size LxWxH (mm) |

350 × 450 x 480 |

715 × 865 x 1055 |

1010 × 1000 x 1380 |

930 × 1570 x 1750 |

| Weight | 30 kg | 180 kg | 300 kg | 750 kg |

Green Blue Corporation